ARCH CARE

QUALITY AND SYSTEM

"I have been in this industry for more than 20 years from worker to spare parts purchaser and now as QC manager for ARCH.

When it comes to quality control in China things can get complicated and suspicious very fast. Most of the time, this is the final client who is paying for such kind of irresponsible behavior.

Experience, independence, good process but also a special talent on solving the quality problem without «making losing face to the factory» is what is needed to ensure quality!

To guarantee the quality of your products is my commitment to you!"

MEETING YOUR QUALITY REQUIREMENT

We can meet any of your quality requirements. We are expert in the production of luggage.

Our quality system has been established and approved for more than 7 years…and still today we are improving our methods to bring you the best satisfaction in terms of quality of production.

Our bags may comply with all International standard such TOV, CSCV, SGS, TUV, ITS, REACH etc.

We guarantee our quality of product (based on your quality requirement). If Arch fails to his commitment we take full responsibilities (remake the goods or refund you the money).

KEEPING THE CONTROL WITH OUR DEDICATED QC TEAM FROM THE SUPPLIES TO THE LOADING

CHINESE CONTEXT, TRUST ISSUE AND EXPERIENCE

When it comes to quality control in China it could become very tricky and a very sensitive matter for the factory but as well for you. When quality problems are found, most of factories are trying to hide the problem or to bribe the QC (3rd part QC). To solve that problem, ARCH has hired its own team of QC. They work independently from the factory. ARCH has created very strict rules for them in order to avoid the temptation of getting extra money.

WE CONTROL YOUR PRODUCTION FROM THE SUPPLIES UP TO THE LOADING.

Quality is not only quality of production. It is also and especially the control of the supplies before starting the mass production. It is also to control the loading of the goods into the container for a safe journey to your door. That is why our QC’s are checking your goods during all the process of production up to loading.

A KEY STEP – PREPARATION OF THE QC

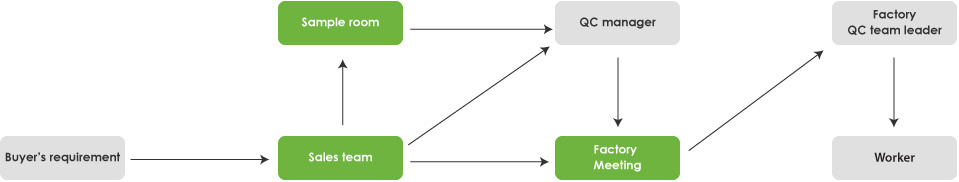

SALES TEAM

They analyze first your request and explain the detail of your project in Chinese language for the sample room.

They give also special recommendation to the sample room about the price and quality level expected.

The same information is explained as well to the QC team.

When the sample is approved by you, the sale is sending the final sample to QC for the production control.

SAMPLE ROOM

Before sampling, our technicians are thinking again and again on your project for optimizing all the costs (supplies/production procedure) in order to offer you the most competitive price or for reaching your target price. While sampling they also write a list of technical comments for the mass production.

FACTORY MEETING

Sales and QC are participating to a «pre production meeting» with the production team in order to explain all the details of your order and its specificity.

Focus is made on complicated production procedure, quality points and packing details.